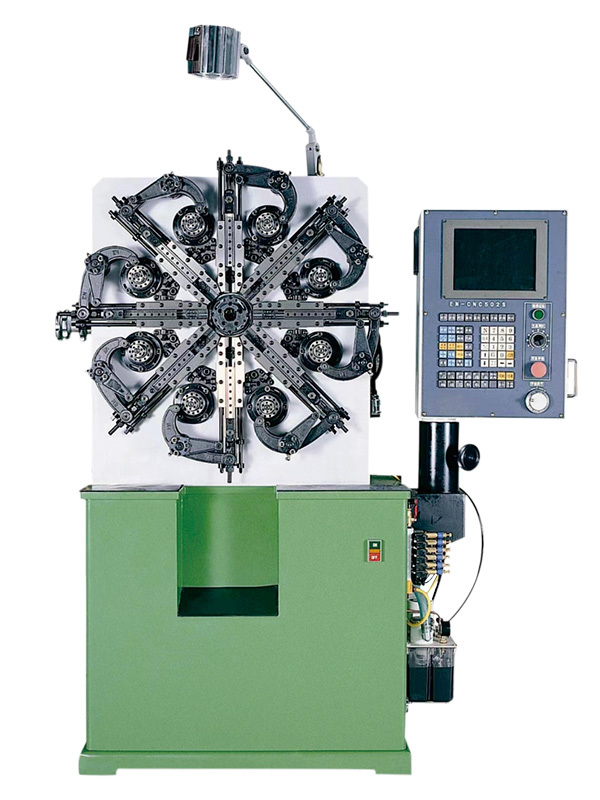

Introduction to the basic working principle of a spring machine

2019-12-10

The basic working principle of a spring machine can be divided into several processes: straightening mechanism, feeding mechanism, diameter changing mechanism, pitch control mechanism, and cutting mechanism.

1. Straightening Mechanism: The straightening mechanism is located between the material rack and the feeding roller. It consists of two sets of straightening rollers. The purpose of the straightening system is to eliminate the original bending deformation of the wire, so that it can enter the forming machine straightly to improve the accuracy of the spring.

2. Feeding Mechanism: The feeding mechanism is a device that uses one or two pairs of feeding rollers to clamp the wire, and the rotation of the feeding rollers drives the wire to move forward linearly. It is achieved by using a fan-shaped incomplete gear to drive the gear on the feeding roller shaft. The speeds of the upper and lower rollers are the same, but the rotation directions are opposite. When the feeding roller rotates one revolution, the feeding length is the circumference of the feeding roller. The expansion length of the spring can be determined by the number of rotations of the feeding roller. The number of teeth of the fan-shaped incomplete gear controls the number of rotations of the feeding roller (refer to the coefficient table for details).

3. Diameter Changing Mechanism: The diameter changing mechanism refers to the control mechanism of the outer diameter of the spring when winding the spring. It consists of two push rods and a diameter changing cam that drives the push rods. When producing cylindrical springs, the wire path remains unchanged. Adjust the two push rods to the corresponding positions to meet the outer diameter of the spring, and then fix the positions of the two push rods. When producing variable diameter springs, such as convex and truncated cone springs, loosen the two bolts at the front and rear of the upper push rod, allowing the push rod to retract in the tool holder to change the outer diameter of the spring. The diameter changing cam drives the push rod to achieve the purpose of producing various variable diameter springs.

4. Pitch Changing Mechanism: The pitch changing mechanism is the mechanism that controls the pitch of the spring. This machine has two mechanisms:

(1) It consists of a pitch knife and a pitch cam. The pitch cam controls the effective number of coils of the spring, and the bolt under the pitch knife adjusts the height of the spring;

(2) It uses a cam-driven connecting rod to push the pitch knife out from the inside of the machine to better increase the pitch of the spring.

5. Cutting Mechanism: The cutting mechanism is the last processing action after winding and forming, cutting the wire to make the spring fall. It is completed by the knife and the core during cutting.

Previous page:

Tel:

E-Mail:

ADD:

Fujisource Industrial Park, Building D, Sandong Town, Huizhou City, Guangdong Province

Power by:www.300.cn | SEO | Privacy Policy